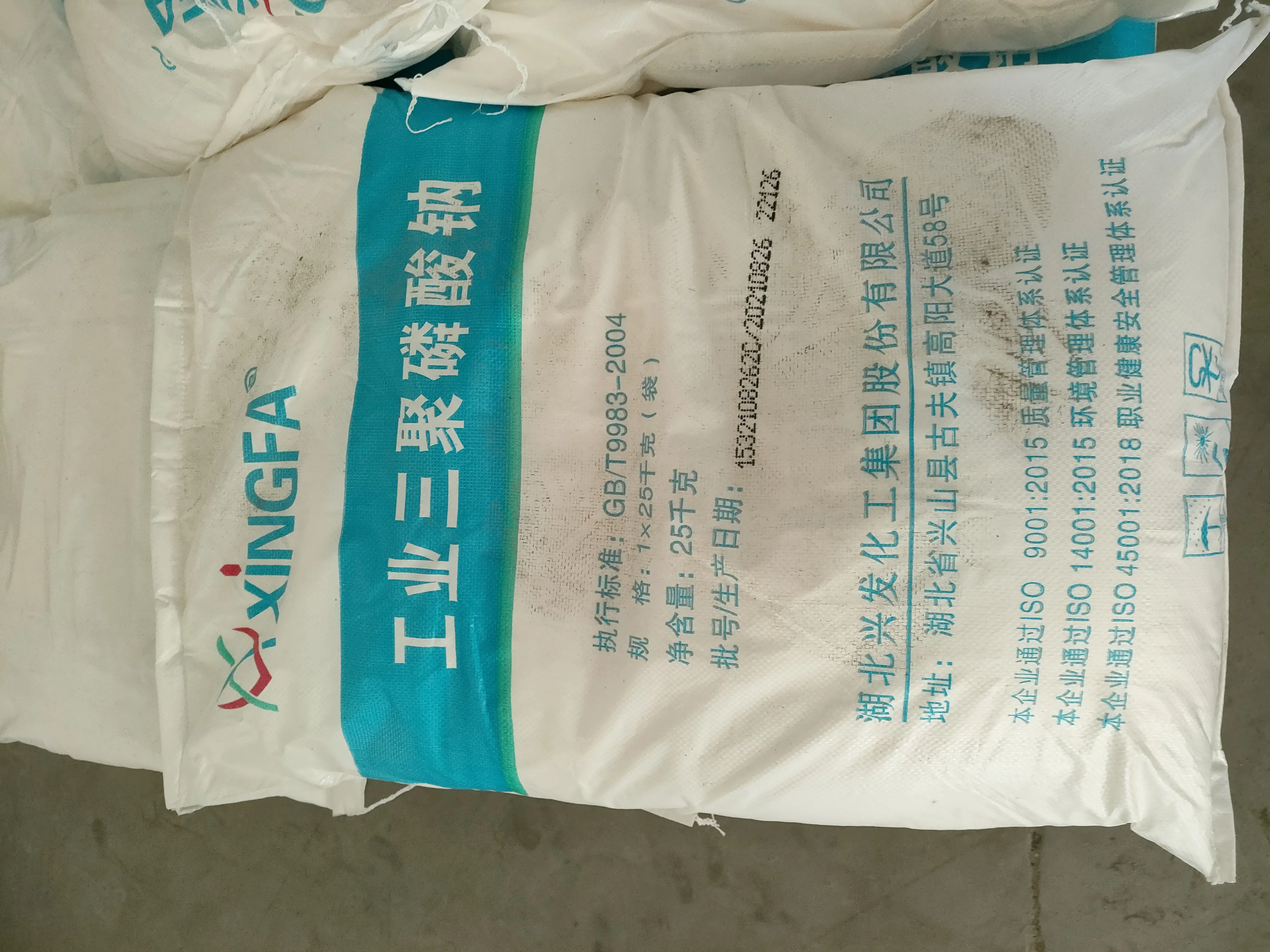

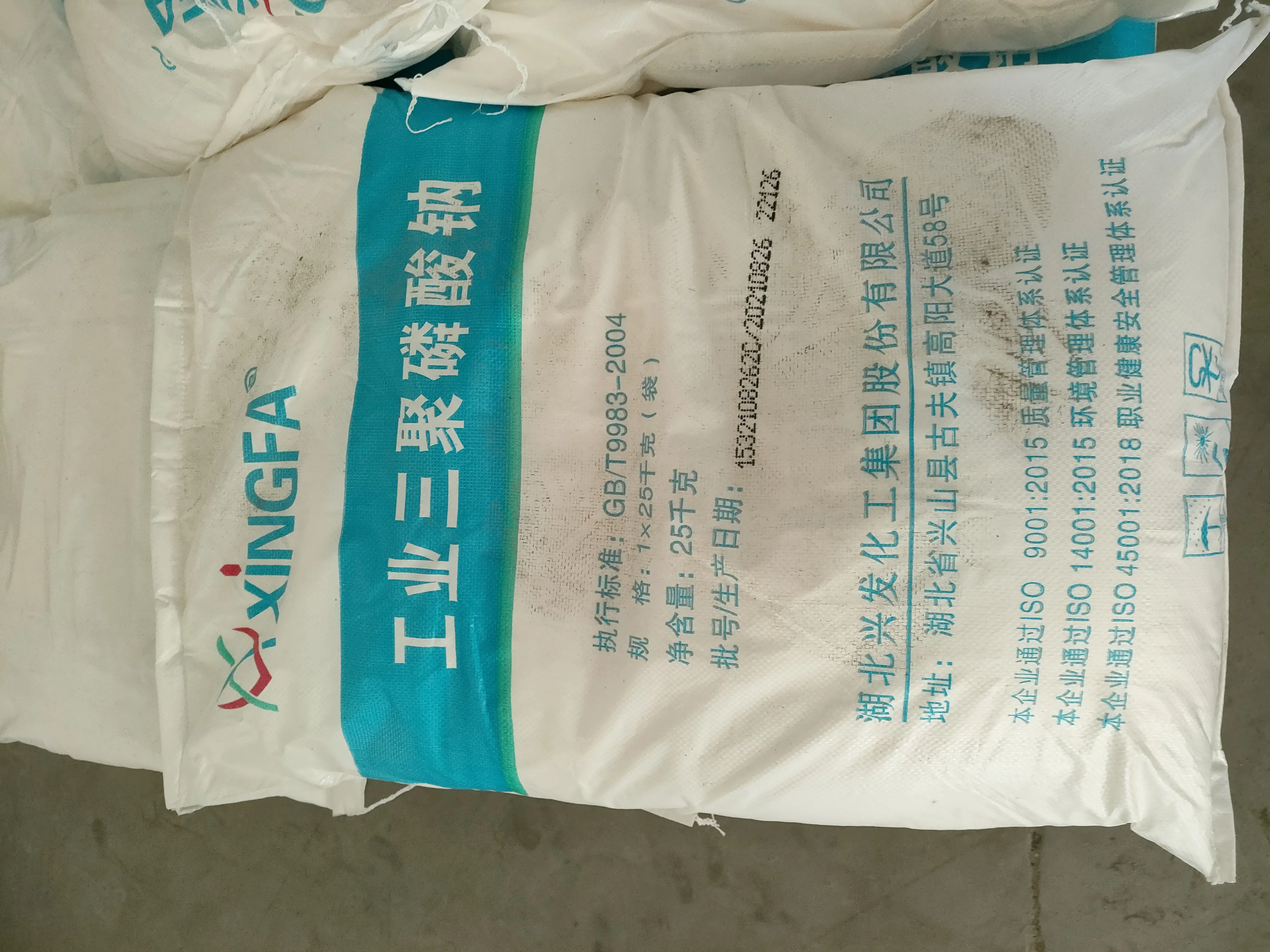

1.三聚海外npv加速器试用分类代码(GBl5.003.INS451(i))。化学结构:本品为一种无定形水溶性线性聚磷酸酯,两端以Na2PO4封端。其化学式为Na5P3O10.相对分子量为367.86.常用于食品中,作为保水剂、品质改良剂、pH调节剂和金属螯合剂。

1. Classification code for sodium tripolyphosphate (GBl5.003. INS451 (i)). Chemical structure: This product is an amorphous water-soluble linear polyphosphate ester, with both ends capped with Na2PO4. Its chemical formula is Na5P3O10. The relative molecular weight is 367.86. It is commonly used in food as a water retaining agent, quality improver, pH regulator, and metal chelating agent.

2.

顺酐生产厂家提醒您,该产品对眼睛、呼吸系统和皮肤有影响,避免接触皮肤和眼睛。接触眼睛后,请立即用大量水冲洗,咨询医生并穿上适当的防护服。储存在密封的容器中,放在阴凉、干燥和通风良好的地方,远离不相容的物质。储存有利于保护的水分。

2. The manufacturer of maleic anhydride reminds you that this product has an impact on the eyes, respiratory system, and skin. Avoid contact with the skin and eyes. After contact with eyes, immediately rinse with plenty of water, consult a doctor, and wear appropriate protective clothing. Store in a sealed container, in a cool, dry, and well ventilated place, away from incompatible substances. Store moisture that is beneficial for protection.

3.三聚海外npv加速器试用是用纯碱中和磷酸形成正海外npv加速器试用,然后浓缩而成。生产磷酸有两种方法:湿法和热法。湿法是磷矿与无机酸(一般是硫酸或盐酸)反应,然后经过萃取、精制得到磷酸。热法是用焦炭和二氧化硅在电炉中焙烧磷矿,将磷矿还原成磷,然后氧化水合得到磷酸。

3. Sodium tripolyphosphate is formed by neutralizing phosphoric acid with soda ash to form sodium orthophosphate, which is then concentrated. There are two methods for producing phosphoric acid: wet method and thermal method. Wet process involves the reaction of phosphate rock with inorganic acids (usually sulfuric acid or hydrochloric acid), followed by extraction and refinement to obtain phosphoric acid. The thermal method uses coke and silicon dioxide to calcine phosphate rock in an electric furnace, reduce the phosphate rock to phosphorus, and then oxidize and hydrate to obtain phosphoric acid.

4.由正磷酸盐制备三聚海外npv加速器试用的工艺简单,流程短,便于控制和操作。主要有两种方法。

The process of preparing sodium tripolyphosphate from orthophosphate is simple, short, and easy to control and operate. There are two main methods.

5.喷雾干燥-转化器缩聚两步法:喷雾干燥器是一个圆筒,其上部连接一个带煤气喷嘴的卧式燃烧器。温度为400500的气体通过燃烧器引入喷雾干燥塔的上部,正磷酸盐溶液由高压泵(4.2MPa)注入。含水量低于5%的干燥产品从干燥机的下部连续取出。

5. Two step spray drying converter polycondensation method: the spray dryer is a cylinder, and its upper part is connected to a horizontal burner with a gas nozzle. The gas with a temperature of 400500 is introduced into the upper part of the spray drying tower through the burner, and the orthophosphate solution is injected by the high-pressure pump (4.2MPa). Dry products with a moisture content below 5% are continuously taken out from the lower part of the dryer.

6.正磷酸盐混合物在回转炉中脱水并浓缩成三聚海外npv加速器试用。这种方法的特点是产品不需要粉碎,喷雾干燥机干燥效率高,干燥后的物料非常均匀,不会出现分层。缺点是干燥和缩聚分两个阶段进行,直接加热脱水粉尘损失大。

6. The orthophosphate mixture is dehydrated in a rotary furnace and concentrated into sodium tripolyphosphate. The characteristics of this method are that the product does not need to be crushed, the spray dryer has high drying efficiency, and the dried materials are very uniform without stratification. The disadvantage is that drying and polycondensation are carried out in two stages, and direct heating and dehydration result in significant dust loss.

7.一段干燥脱水法:将浆料喷入回转炉内,通过喷嘴将热气送入炉内或烧油加热。环形挡板将炉膛分成火焰段和加热段。在加热段,物料终脱水、缩聚并转化为三聚海外npv加速器试用。

7. One stage drying dehydration method: Spray the slurry into the rotary furnace, and use a nozzle to send hot gas into the furnace or burn oil for heating. The annular baffle divides the furnace into a flame section and a heating section. In the heating section, the material is finally dehydrated, condensed, and converted into sodium tripolyphosphate.

如果人们过多地接触三聚海外npv加速器试用,会对他们的健康造成很大的危害。比如会对眼睛造成明显的不适。如果人们吸入这种物质,可能会引起恶心和呕吐等一些肠道反应。所以要多加注意,更多事项就来咨询我们

http://www.jnjhhg.cn吧!

If people are excessively exposed to sodium tripolyphosphate, it can cause great harm to their health. For example, it can cause obvious discomfort to the eyes. If people inhale this substance, it may cause some intestinal reactions such as nausea and vomiting. So you need to pay more attention and consult us for more matters http://www.jnjhhg.cn Come on!