专注品质,信赖服务

我们用心做产品服务

咨询热线:

13655318786

专注品质,信赖服务

我们用心做产品服务

咨询热线:

13655318786

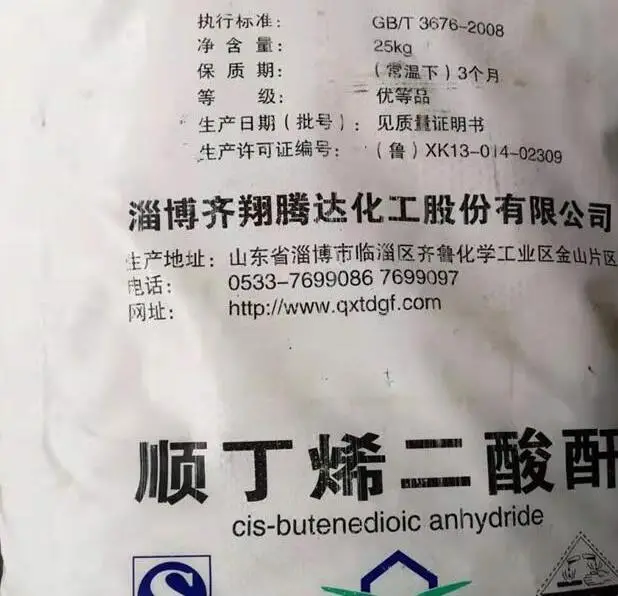

顺酐全称为顺丁烯二酸酐、马来酸酐,化学式为C4H2O3,室温下表现为针状白色晶体,有明显刺激性气味,具有易燃、易溶于水、易升华等特点,是一种非常重要的精细化工品和有机化工原料。是目前世界上次于苯酐和醋酐旳第三大酸酐,经过多年发展,顺酐应用领域逐渐拓宽,多用于生产不饱和聚酯树脂(UPR),也是生产造纸助剂、酒石酸、油墨助剂、医药、涂料、润滑油添加剂等产品的核心化学原料。

Maleic anhydride, also known as maleic anhydride or maleic anhydride, has a chemical formula of C4H2O3. It appears as a needle shaped white crystal at room temperature and has a clear irritating odor. It is flammable, soluble in water, and easily sublimated, making it a very important fine chemical and organic chemical raw material. It is currently the third largest anhydride in the world after phthalic anhydride and acetic anhydride. After years of development, the application field of maleic anhydride has gradually expanded, mainly used in the production of unsaturated polyester resin (UPR). It is also the core chemical raw material for the production of paper additives, tartaric acid, ink additives, pharmaceuticals, coatings, lubricant additives, and other products.

顺酐应用领域广泛,主要用于生产不饱和聚酯树脂UPR,也是生产油墨助剂、造纸助剂、增塑剂、酒石酸、富马酸、四氢呋喃(THF)等的有机化工原料,目前不饱和树脂占比,主要品种包括邻苯型、间苯型、对苯型、双酚A型等,按用途和功能分类包括通用树脂、耐化学品树脂、阻燃树脂、浇注树脂、柔性树脂、人造大理石、BMC与DMC树脂、装饰类树脂和特种树脂等,通常占顺酐总消费量的40%~50%。

Maleic anhydride has a wide range of applications and is mainly used in the production of unsaturated polyester resin UPR. It is also an organic chemical raw material for the production of ink additives, papermaking additives, plasticizers, tartaric acid, fumaric acid, tetrahydrofuran (THF), etc. Currently, the proportion of unsaturated resins is the highest, and the main varieties include ortho benzene type, meta benzene type, para benzene type, bisphenol A type, etc. According to their use and function, they include general resins, chemical resistant resins, flame retardant resins, casting resins, etc Flexible resins, artificial marble, BMC and DMC resins, decorative resins, and special resins typically account for 40% to 50% of the total consumption of maleic anhydride.

顺酐的生产工艺大致可分为苯氧化法、正丁烷氧化法、苯酐副产法、C4烯烃法等。其中,苯氧化法和正丁烷氧化法是应用广泛的顺酐生产方法。苯氧化法是早的顺酐生产工艺,这种方法生产技术较成熟,可选催化剂的种类较多,但具有高成本、高污染等缺点。随着我国要求逐渐严格,以及新兴正丁烷氧化法技术逐渐成熟,具有性价比高、绿色等优势,正丁烷氧化法逐渐取代了苯氧化法。目前,正丁烷氧化法在我国整体顺酐产能中的占比已经达到90%。

The production process of maleic anhydride can be roughly divided into benzene oxidation method, n-butane oxidation method, phthalic anhydride by-product method, C4 olefin method, etc. Among them, benzene oxidation and n-butane oxidation are the most widely used methods for producing maleic anhydride. The benzene oxidation method is the earliest production process of maleic anhydride. This method has mature production technology and a variety of optional catalysts, but it has disadvantages such as high cost and high pollution. With the increasingly strict environmental requirements in our country and the maturity of emerging n-butane oxidation technology, which has advantages such as high cost-effectiveness and green environmental protection, the n-butane oxidation method has gradually replaced the benzene oxidation method. At present, the proportion of n-butane oxidation method in the overall production capacity of maleic anhydride in China has reached 90%.

正丁烷氧化法生产顺酐比苯氧化法单耗低,原料消耗,环境污染小,正丁烷氧化法取代苯氧化法是顺酐技术发展的趋势。

The production of maleic anhydride using the n-butane oxidation method has lower unit consumption, lower raw material consumption, and less environmental pollution than the benzene oxidation method. The trend of maleic anhydride technology development is to replace the benzene oxidation method with the n-butane oxidation method.

本文由顺酐生产厂家整理发布,您是不是对这些内容有所了解了呢?更多的内容请点击:http://www.jnjhhg.cn我们会有更多精彩内容等你查看

This article is organized and published by maleic anhydride manufacturers. Do you have any understanding of these contents? For more information, please click on: http://www.jnjhhg.cn We will have more exciting content waiting for you to view

上一篇:丙二醇的详细应用特点介绍

下一篇:顺丁烯二酸酐结构式和鉴别