专注品质,信赖服务

我们用心做产品服务

咨询热线:

13655318786

专注品质,信赖服务

我们用心做产品服务

咨询热线:

13655318786

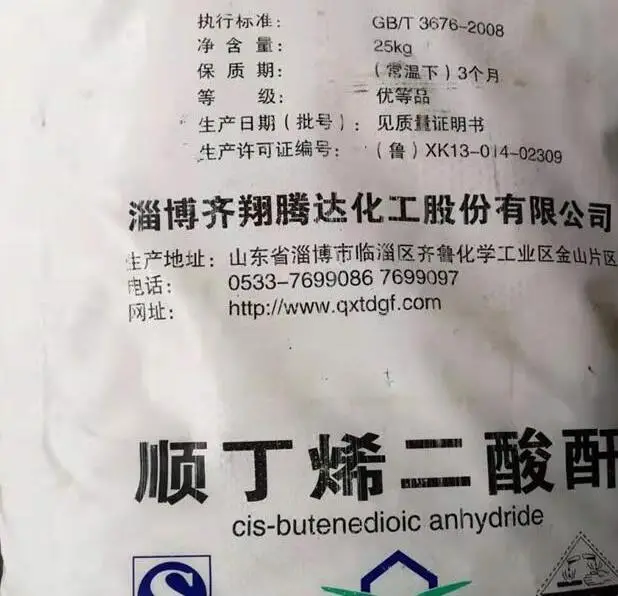

顺酐法BDO,顾名思义是以顺酐为原料制备BDO的工艺,其原料顺酐可由苯或者丁烷氧化制成。由于环境污染问题,国内苯法顺酐装置长期处于停产状态或者经过改造以丁烷氧化制顺酐,目前全球80%顺酐产能都采用固定床丁烷法,具有原料易得、污染小、产品收率高等特点。

The maleic anhydride method BDO, as the name suggests, is a process of preparing BDO from maleic anhydride, which can be made by oxidation of benzene or butane. Due to environmental pollution issues, the domestic benzene based maleic anhydride plant has been in a long-term shutdown state or has undergone transformation to produce maleic anhydride through butane oxidation. Currently, 80% of the global maleic anhydride production capacity adopts the fixed bed butane method, which has the characteristics of easy access to raw materials, low pollution, and high product yield.

顺酐法,根据顺酐加氢时的步骤不同可分为直接加氢法与间接加氢法,间接加氢法中根据加氢时的物料形态又可分为气相加氢法与液相加氢法。

The maleic anhydride method can be divided into direct hydrogenation method and indirect hydrogenation method based on the different steps of maleic anhydride hydrogenation. In the indirect hydrogenation method, it can be further divided into gas-phase hydrogenation method and liquid-phase hydrogenation method based on the material morphology during hydrogenation.

直接加氢与间接加氢

Direct hydrogenation and indirect hydrogenation

直接加氢法

Direct hydrogenation method

顺酐直接加氢工艺是20世纪60年代早由三菱油化以及三菱化成公司联合开发成功的。该工艺能够同时生产不同比例的THF (四氢呋喃)、GBL (y-丁内酯)和BDO等系列产品,反应条件不同,其产品的相应组成也是不同的。

The direct hydrogenation process of maleic anhydride was first successfully developed by Mitsubishi Oil and Chemical Corporation in the 1960s. This process can simultaneously produce series products such as THF (tetrahydrofuran), GBL (y-butyrolactone), and BDO in different proportions. The corresponding composition of the products varies depending on the reaction conditions.

酯化加氢法

Esterification hydrogenation method

间接酯化加氢工艺早是由英国Davy公司开发成功的,因此又叫Davy法。加氢反应可以在气相或者是液相中进行,采用了铜系催化剂,主体反应的条件要比顺酐直接加氢工艺温和很多。

The indirect esterification hydrogenation process was first developed by Davy Company in the UK, hence it is also known as the Davy method. Hydrogenation reactions can be carried out in gas or liquid phases, using copper based catalysts. The main reaction conditions are much milder than those of direct hydrogenation of maleic anhydride.

由于顺酐加氢是强放热反应,直接加氢反应条件苛刻,控制难度高,目前还没有工业化运行装置,在运装置均采用的是间接法。

Due to the strong exothermic reaction of maleic anhydride hydrogenation, the direct hydrogenation reaction conditions are harsh and difficult to control. Currently, there is no industrial operation device, and the indirect method is used in the operating devices.

气相加氢与液相加氢

Gas phase hydrogenation and liquid phase hydrogenation

两者化学反应方程式是一致的,区别在于加氢单元马来酸二甲酯是在气相还是在液相条件下反应。

The chemical reaction equations of the two are consistent, with the difference being whether the hydrogenation unit dimethyl maleate reacts under gas or liquid phase conditions.

气相加氢顺酐法,是在进行加氢反应时,将所有的物料先气化为气相,再与氢气(同样为气相)反应,终制得BDO,并副产少量THF(根据需要也可以副产少量GBL)。

The gas-phase hydrogenation maleic anhydride method is a hydrogenation reaction in which all materials are first gasified into the gas phase, and then reacted with hydrogen gas (also in the gas phase) to finally produce BDO, with a small amount of THF produced as a byproduct (a small amount of GBL can also be produced as needed).

以意大利Conser为代表的液相加氢顺酐法,则不需要进化步骤,而是直接将液相的物料与氢气(气相)反应制BDO,因此该方法又可称为混合相加氢顺酐法。

The liquid-phase hydrogenation maleic anhydride method, represented by the Italian Conser, does not require gasification steps, but directly reacts the liquid-phase material with hydrogen (gas phase) to produce BDO. Therefore, this method can also be called the mixed phase hydrogenation maleic anhydride method.

目前多数技术公司的工艺是气相加氢工艺。

At present, most technology companies use gas-phase hydrogenation technology.

消耗与排放

Consumption and emissions

正丁烷顺酐法制BDO工艺路线,生产吨BDO的主要消耗大致为正丁烷1.15t、氢气1200 m3。该法的主要原料为正丁烷和氢气,正丁烷的按5000元/t计算,生产BDO的原料成本约1. 05万元/t;如果外购顺酐生产BDO,目前顺酐的市场价约为1. 2万元/t,吨BDO消耗顺酐1.12t左右,BDO的生产成本较高。

The BDO process route using n-butane maleic anhydride produces approximately 1.15 tons of n-butane and 1200 m3 of hydrogen gas per ton of BDO. The main raw materials for this method are n-butane and hydrogen gas. The price of n-butane is calculated at 5000 yuan/t, and the raw material cost for producing BDO is about 1 050000 yuan/t; If purchasing maleic anhydride to produce BDO, the current market price of maleic anhydride is about 1 20000 yuan/t, with a consumption of about 1.12 tons of maleic anhydride per ton of BDO, the production cost of BDO is relatively high.

本文由顺酐生产厂家友情奉献.更多有关的知识请点击:http://www.jnjhhg.cn真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待

This article is a friendly contribution from maleic anhydride manufacturers. For more information, please click: http://www.jnjhhg.cn Sincere attitude. We will provide you with comprehensive services. We will gradually contribute more relevant knowledge to everyone. Stay tuned

上一篇:顺酐的密度及相关知识

下一篇:顺酐的需求量与供应量并不匹配